Functional Safety in Automotive

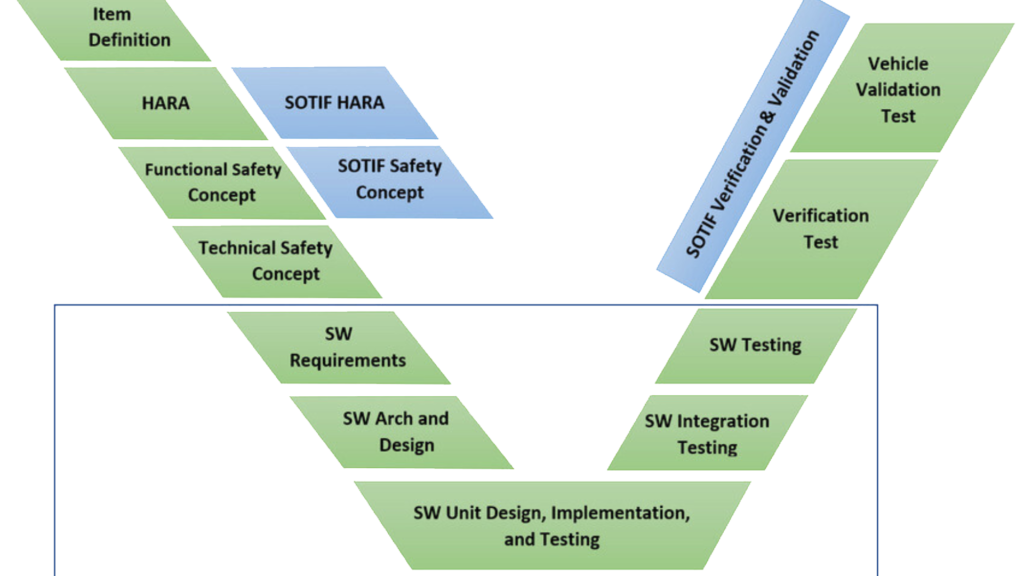

Automotive functional safety implements protective measures to eliminate hazards caused by failure or unintended behavior of a vehicle-level system. The ISO 26262 standard offers automotive manufacturers and their suppliers a comprehensive set of guidelines to guarantee the attainment of functional safety throughout every stage of product design. It sets out criteria for the safety-critical functions of a system, as well as the processes, techniques, and tools utilized during the development phase. This standard is instrumental in guaranteeing that the vehicle lifecycle maintains and upholds adequate safety levels.

Our Automotive experts are well-versed with ISO 26262 and follow a systematic approach to achieve functional safety in automotive systems. From hazard analysis and risk assessment to defining safety goals and requirements, our process is meticulous and thorough. Our team of expert engineers ensures that safety mechanisms, redundancies, and fail-safe features are integrated into the system architecture. Throughout the development process, we conduct rigorous verification and validation activities to guarantee that safety requirements are met and that the system operates as intended.

What We Offer?

Process

– Item Definition

– HARA

– Safety Goals

– ASIL classifications

– DIA (Development Interface Agreement)

– FMEA

– FTA

– ASPICE

– CMMI

Methods

– Software Development

– SW Development SW Verification MC/DC

– Range Check

– Control Flow Monitoring

– ASIL Decomposition

– Coding Guidelines Doc.

Tools Selection & Qualification

– Compiler

– MISRA

– Auto code

– Testing Tool

– Verification

Components selection

– Microcontroller

– AUTOSAR SW

– HW components

Compliance

– MISRA

– ASIL level

– Requirements

– Tools

– ASPICE/CMMI

Safety Team

– Overview Training

– ISO 26262 Certifications

BENEFITS

Increases safety reduces the probability of accidents and fatalities

Increases reliability by means of verification and validation

Reduces OEM’s and suppliers’ liability

Improves quality with improved and relevant processes